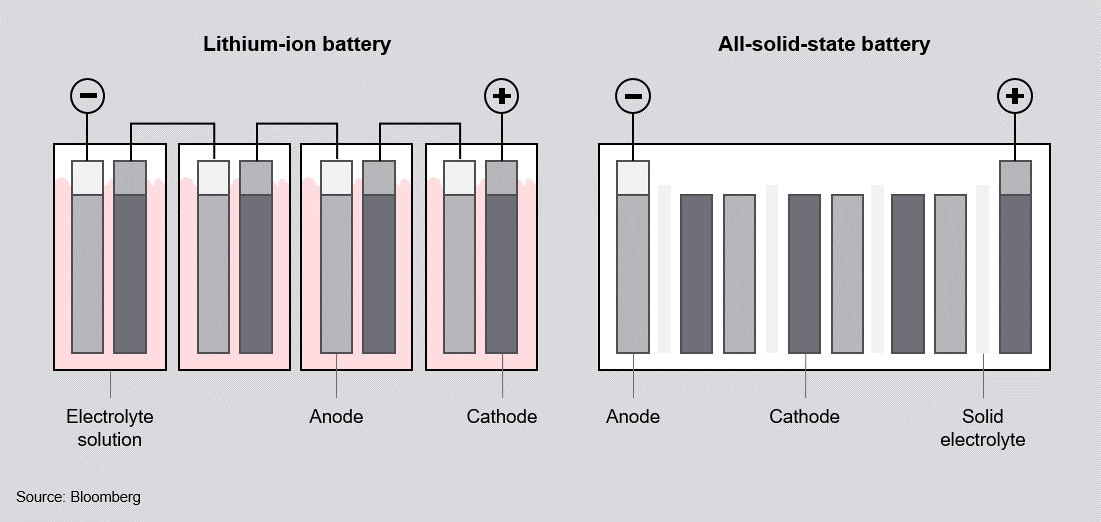

Today, Li-ion batteries are all around us, from various electronic devices such as smartphones and laptops to electric vehicles, the numbers of which are steeply rising to move away from the fossil fuel-based economy 1, 2. Thus, the whole process is very electron-dose efficient and offers quick screening of potential coatings. The high volume changes of Si nanoparticles during (de)lithiation allow monitoring of the coating behavior at a relatively low magnification. The current protocol presents an alternative procedure in which the potential coatings are applied on Si nanoparticles and are subjected to (de)lithiation during operando TEM experiments. However, the accumulated electron dose during a typical high-resolution in situ work may affect the electrochemical pathways, evaluation of which can be time-consuming. Operando transmission electron microscopy (TEM) couples high spatial resolution with high temporal resolution to allow visualization of dynamic processes, and thus is an ideal tool to evaluate electrode/electrolyte coatings via studying (de)lithiation at a single particle level in real-time. For this, researchers are screening potential electronic/ionic conductive and nonconductive coatings to find the best coatings with suitable thickness for long-term chemical, electrochemical, and mechanical stability. Applying a suitable coating around the electrode and/or electrolyte particles offers a convenient solution, leading to better performance. However, in the ASSB, the ion transportation through the solid-solid electrolyte-electrode interface poses a challenge due to contact and chemical/electrochemical stability issues. Thus, the all-solid-state batteries (ASSBs) that use solid electrolytes instead of liquid electrolytes, which reduce the risk of flammability, have been the center stage of battery research for the last few years. With the ever-increasing use of Li-ion batteries, especially due to their adoption in electric vehicles, their safety is in prime focus.

0 kommentar(er)

0 kommentar(er)